BATTERY SETUP FOR YOUR 4WD! DETAILED ANALYSIS OF UNDER BONNET APPLICATIONS.

We get asked always, is it okay to install the DCS lithium batteries under vehicle bonnets? In short, yes. Why wouldn’t you when the DCS LFP cells have a more comprehensive operating temperature range than AGM cells, are safer, more robust, less likely to degas at extreme temperatures and have a significantly longer lifespan. Let us further elaborate below on the facts.

AGM cells have been traditionally used for high cold cranking amp requirements as they have good cold-temperature characteristics compared to other lead-acid cells. However, on the flip side, they don’t like the heat. AGM’s and other sealed type batteries (SLA or VRLA) do not like heat and should be installed away from engine compartments. Manufacturers recommend stopping charging when the batteries are subject to temperatures above 50 degrees C as the cells degrade significantly with temperatures already above 25 Degrees C.

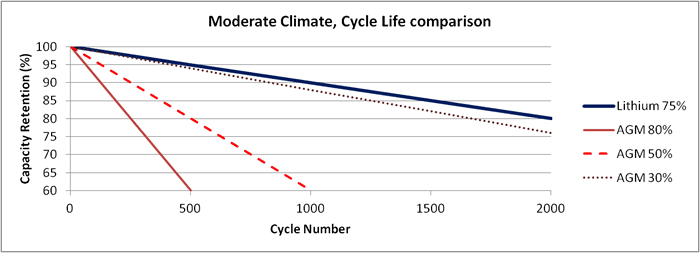

Lithium Iron Phosphate (LiFePO4 or LFP) cells have a significantly higher cycle life than AGM cells, especially under deep cycle discharge applications. The disparity is further increased as ambient temperatures rise. The cycle life of each chemistry can be increased by limiting the depth of discharge (DoD), discharge rate, and temperature, but lead-acid is much more sensitive to each of these factors.

The below graph shows the capacity retention % Vs cycle life of AGM cells and Lithium LFP cells when subject to moderate/average temperatures (25 degrees C). Which is also the temperature at which manufacturers specify their cell capacities.

AGM Vs LFP at 25 Degrees C.

As the depth of discharge influences cycle life, the figure shows multiple DOD percentages for the lead-acid. It can be seen that the AGM pack must be limited to a 30% depth of discharge to get comparable life to a lithium-ion that is at 75% depth of discharge. This means that the AGM battery must be 2.5 times larger in capacity than the lithium-ion to get comparable life at average temperatures.

Generally speaking, at DCS, we usually tell customers to work on a 2:1 ratio. For every 200Ah of AGM battery, you only need 100Ah of DCS LFP for similar usable storage. So what happens under extreme under bonnet temperatures, you must be wondering? The thing certainly does heat up.

The below graph shows average temperatures of 50 Degrees C. The disparity between AGM and LFP is further exacerbated.

AGM Vs LFP at 50 Degrees C.

It can be seen that the AGM pack, even when limited to a 30% depth of discharge (DOD), can only do around 1700 cycles with 60% capacity retention. The lithium-ion cell cycling down to a 75% depth of discharge is capable of 2000 cycles with an 80% capacity retention. The AGM cell would need to be limited to around 5% DOD to have a chance. This means that the AGM battery must be at least four times larger in capacity than the lithium-ion to get comparable life at these extreme temperatures.

So why have so many 4WD enthusiasts been installing AGM batteries under bonnets for years? And complaining about the terrible lifespan? Is it a lack of knowledge or misleading information passed on by those national-based battery retailers? One can only speculate, but at least now there is a superior deep cycle 12V battery on the market, the DCS 12V lithium under bonnet battery.

Just to clear up some myths;

- It is a myth that LFP (Lithium Iron Phosphate) batteries are more dangerous under extreme temperatures. It’s the exact opposite. LFP cells have a much more comprehensive, safer and more robust operating temperature range, as seen in the above graphs.

- Apparently, LFP batteries cannot be connected directly to vehicle alternators as there is a possibility of overcharging the battery on a long drive. The DCS LFP batteries have an internal BMS (Battery Management System). Even if the voltage regulator malfunctions in the alternator, there is no possibility of overcharging the DCS batteries on long drives. Most modern vehicles are now fitted with “smart alternators”. These are even better for the DCS 12V batteries as they will maintain a lower overall voltage on the battery packs, which will only further improve the lifespan. Remember from the graphs above, “The cycle life of each chemistry can be increased by limiting the depth of discharge (DoD)”. A smart alternator does precisely that by limiting the charging voltages to conserve fuel.

So why are the DCS 12V 75Ah batteries so popular for under bonnet applications? It’s because, under extreme bonnet temperatures, a single DCS 12V 75Ah battery can deliver similar usable energy to that of an AGM 12V 300Ah battery. With significantly less weight and room. You don’t need colossal 100Ah & 120Ah batteries under your bonnet.

Recently we upgraded a Mitsubishi Challenger 2014 dual battery system. The customer arrived with;

- 1 x Optima D34 cranking battery

- 1 x Ultimate 120Ah AGM deep cycle battery

- RedArc Isolator with externally mounted switch

- Total weight: 20KGs + 35KGs = 55KGs.

Chockablock packed in there. The customer complained that the cranking battery was struggling after only two years, and he had the override switch on most of the time to crank off both batteries. With what you have just learned, that is no surprise, is it? Also, the amount of space the batteries had taken up the engine cooling performance would have been significantly reduced due to a lack of airflow. The under-bonnet temperatures would have been at extreme levels.

We removed both batteries and replaced them with 2 x DCS 12V 75Ah batteries. One for engine cranking and one for deep auxiliary cycling. Is that enough power? Absolutely. With 750CCA, these tiny batteries will quickly crank over even the largest of V8 turbo diesel.

- 2 x DCS 12V 75Ah batteries

- Matson 140Amp Dual Battery Isolator with integrated switch

The ultimate DCS 12V dual battery setup.

With the isolation cut off, the voltage being 12.8V means that the cranking battery will be able to deep cycle down to around 80% of its capacity before it’s isolated. At 12.8V, the battery will crank over the engine. So with the auxiliary 75Ah + cranking 60Ah (80% DOD) = 135Ah of combined usable storage. For deep cycle accessories such as dual lithium under bonnet battery setup, this more than doubled the existing AGM battery setup, which only had a storage capacity of 120Ah with 50% being usable = 60Ah.

135Ah usable storage with the lithium’s Vs only 60Ah with the AGM’s.

Overall weight dropped from 55KGs to only 20KGs. That’s a weight saving of 35KGs off the nose of the vehicle, which will keep the suspension happier.

The DCS batteries are connected directly to the alternator, which allows the batteries to swallow everything the factory 80Amp alternator can provide, a maximum of around 60-70Amps. These batteries can recharge super fast and are designed to renew at a continuous 100Amps.

With the superior lifespan of the DCS LFP cells, we don’t expect to see this customer again for at least the next ten years. Or maybe his grandchildren if this beast of a tourer gets handed down.