Battery Installation Locations

DCS Batteries that are in a sealed traditional style battery case are IP rated 54 unless otherwise specified.

As there is a considerable amount of electronics inside the battery cases, it is important that these batteries are protected from the ingress of particles and water.

IP54 means that there is partial protection against dust & similar particles & protection against splashing water from any direction for a minimum of 10 minutes.

IP54 MEANS THE BATTERIES ARE NOT WATERPROOF

Our DCS Slimline battery range is IP rated to 53 unless otherwise specified.

IP53 means that there is partial protection against dust & similar particles & protection against splashing water up to 60 degrees from the vertical with limited ingress permitted for 3 minutes.

IP53 MEANS THE BATTERIES ARE NOT WATERPROOF.

DCS batteries should be installed and operated in a location that will not exceed the specified operating temperatures.

Make yourself aware of the new requirements that relate to battery storage, IP ratings and venting. Australian / New Zealand Standards (AS/NZS 3001.2:2022)

Do Not

- Install DCS batteries underneath a vehicle or caravan, or any other external location that is exposed to the atmosphere unless it is fully contained inside a suitable battery housing that will prevent the ingress of particles & or water. Also, sufficient mechanical / structural protection is needed to prevent damage from rocks and debris during recreational vehicle travel.

- Pressure wash or hose your batteries. You can wipe them down with a damp cloth if needed.

- Submerge your batteries in any fluids.

- Install DCS batteries near high heat sources, e.g. exhaust manifolds or turbo chargers.

Operating Temperatures

Each battery has a designated operating temperature range depending on the cell type used.

Our under bonnet Hybrid battery range (using cylindrical cells) is designed to work in ambient temperatures between -30°C to 110°C. Do not operate outside of this temperature range.

Our 12V 180Ah auxiliary batteries have an operating temperature range of -30°C to 60°C. The DCS BMS will not allow these batteries to operate if the 60°C is exceeded.

The DCS BMS will not allow a frozen Battery that is below 0 degrees Celsius to be charged. Charge will only be allowed when the ambient temperature of the battery cell is back above 0°C.

Discontinue the use of a battery immediately if the battery becomes excessively warm whilst in a resting/standby state.

Please check the specifications for the recommended operating temperatures of your particular battery on the DCS website.

www.deepcyclesystems.com.au

Securing your battery

Your battery must be secured to prevent movement. Restraints must prevent any movement under a pulling force of twice the battery weight.

The recommended hold-down bracket torque is 4 N-m. or 3.5 lb-ft.

Care has to be taken to prevent the battery lid seal/gasket from deforming when securing the battery, which could affect the IP rating of the battery. Do Not over-tighten the battery holding clamps.

Battery Charging

Use only approved Lithium-Iron Phosphate specific chargers for your battery’s nominal voltage, chemistry and maximum charge rate with the correct charging stage voltages.

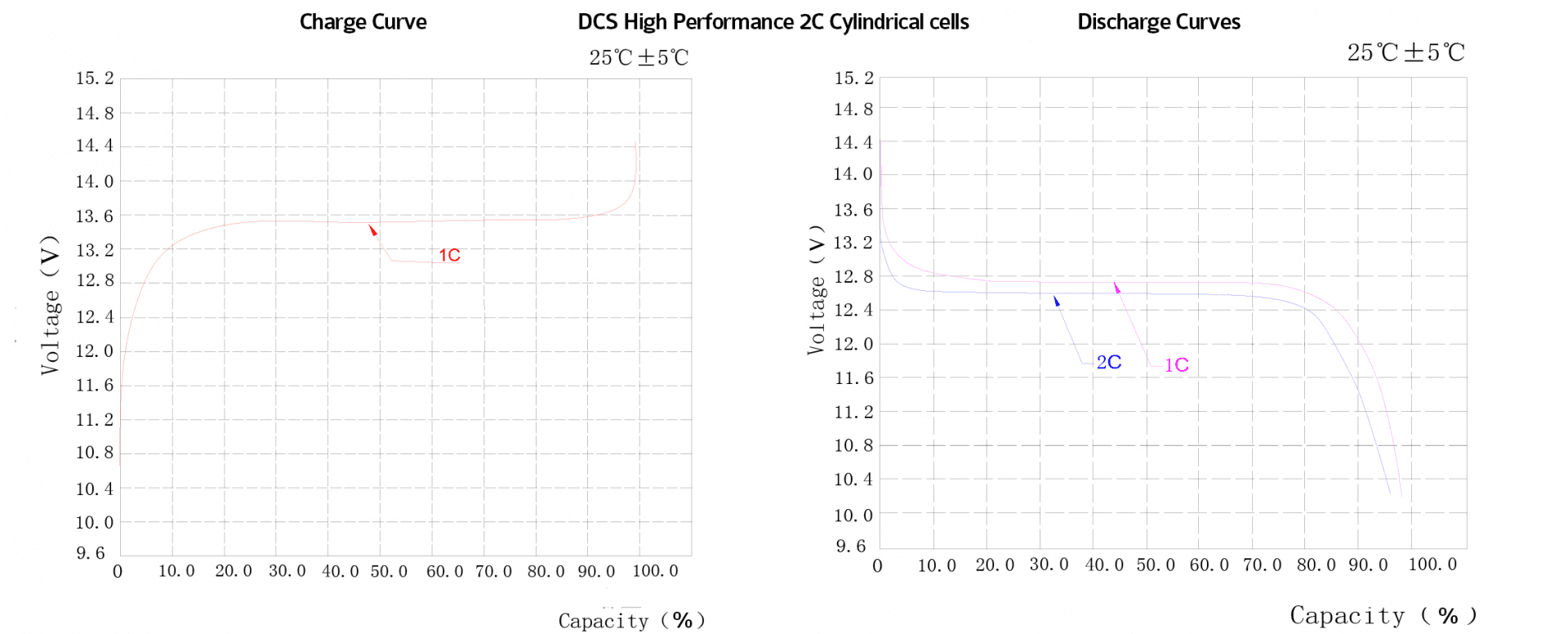

All DCS 12V cylindrical cell packs to be charged at:

14.4V Bulk

13.5V Float

The DCS 12V 180ah Auxiliary prismatic cell pack (SKU: DCS-12V-180ah) to be charged at:

14.2V Bulk

13.5V Float

Be aware some chargers have fixed charging voltages and cannot be adjusted.

Check the charger specifications for charging voltage levels & charging profiles before purchasing.

Alternator Charging

Our under-bonnet dual battery systems, 80ah Extreme & Slimline range, can be charged directly from the vehicle’s alternator, providing that they are the only battery chemistry being charged.

For example, you cannot parallel a Lithium battery to a lead acid battery and charge from the alternator.

This type of set up has to be separated by using a DC-DC Charger.

If you are parallel connecting batteries together, they have to be the same chemistry, nominal voltage, capacity and age.

Each battery has a maximum charge current listed in the specifications table that should not be exceeded; otherwise, permanent damage could be done to the battery.

When the batteries are parallel connected together, this doubles the amount of current the batteries can be charged at.

For example, our DCS 180ah (2 x 90ah ) dual battery system. The maximum charge current is 80 Amps per battery. So 2 x 80A = 160 Amps. This means you can charge these batteries provided your alternator’s max. output does not exceed 160Amps.

Before choosing a battery, check the maximum output current your alternator can produce and also find out the Cold Cranking Amps (CCA) needed to start your vehicle.

Your factory alternator is generally the best alternator to use, and there is no need for high output aftermarket alternators.

Check the specifications table on the DCS website for the particular battery you are interested in, and look for Lithium Cranking Amps (LCA).

If the LCA meets or exceeds the CCA for your particular vehicle, then the battery is suitable for your vehicle.

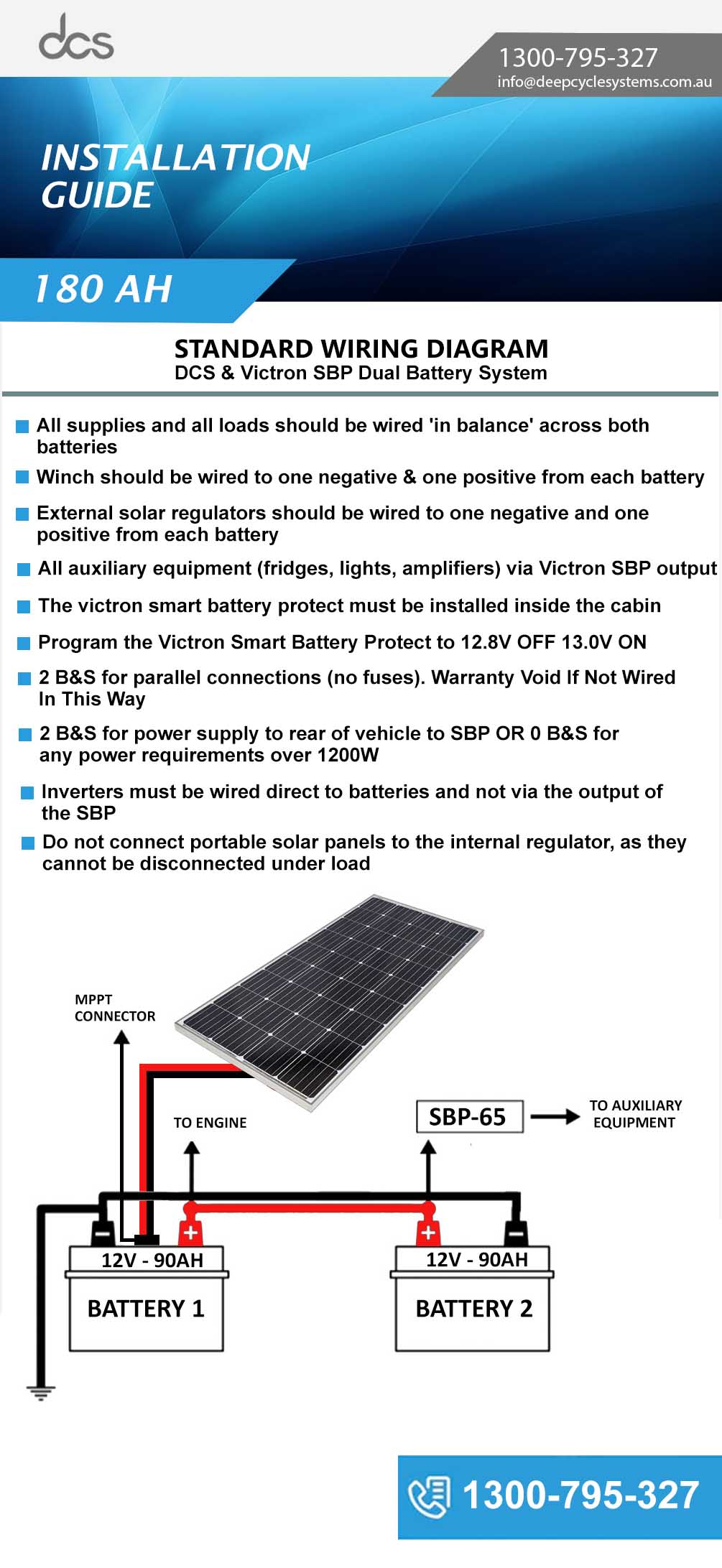

Parallel Connected Batteries

Connect Battery 1 Positive to Battery 2 Positive

Connect Battery 1 Negative to Battery 2 Negative ( This cable is extremely important as some vehicles use the chassis as a negative link, which is prone to failing due to corrosion, which causes a high resistance. )

In Balance Wiring

When you have batteries that are wired in parallel, as described above, it is good practice to wire your loads and inputs in balance.

What this means is, for example, to connect loads & inputs positive to the first battery e.g. Battery 1 and the negative loads & inputs to the last parallel connected battery e.g. Battery 2.

This is important when using an inverter that can have a high current draw so that they evenly draw from the parallel connected batteries.

Storage

If you are not going to be using the battery for some time, charge the battery fully to a 100% state of charge using the correct charging profile and voltages.

Disconnect everything off the battery terminals, and it can be left in this state for up to 3 months.

After 3 months, cycle the battery, fully discharge the battery (11.5 volts), then fully charge the battery, and the battery can then be left in this state for another 3 months.

Do Not

- Use a lead acid charger / maintainer on a Lithium battery.

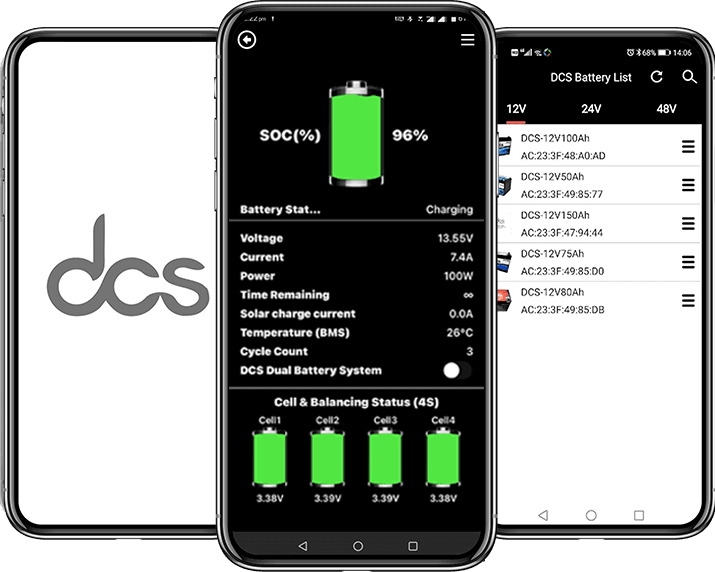

DCS LFP App

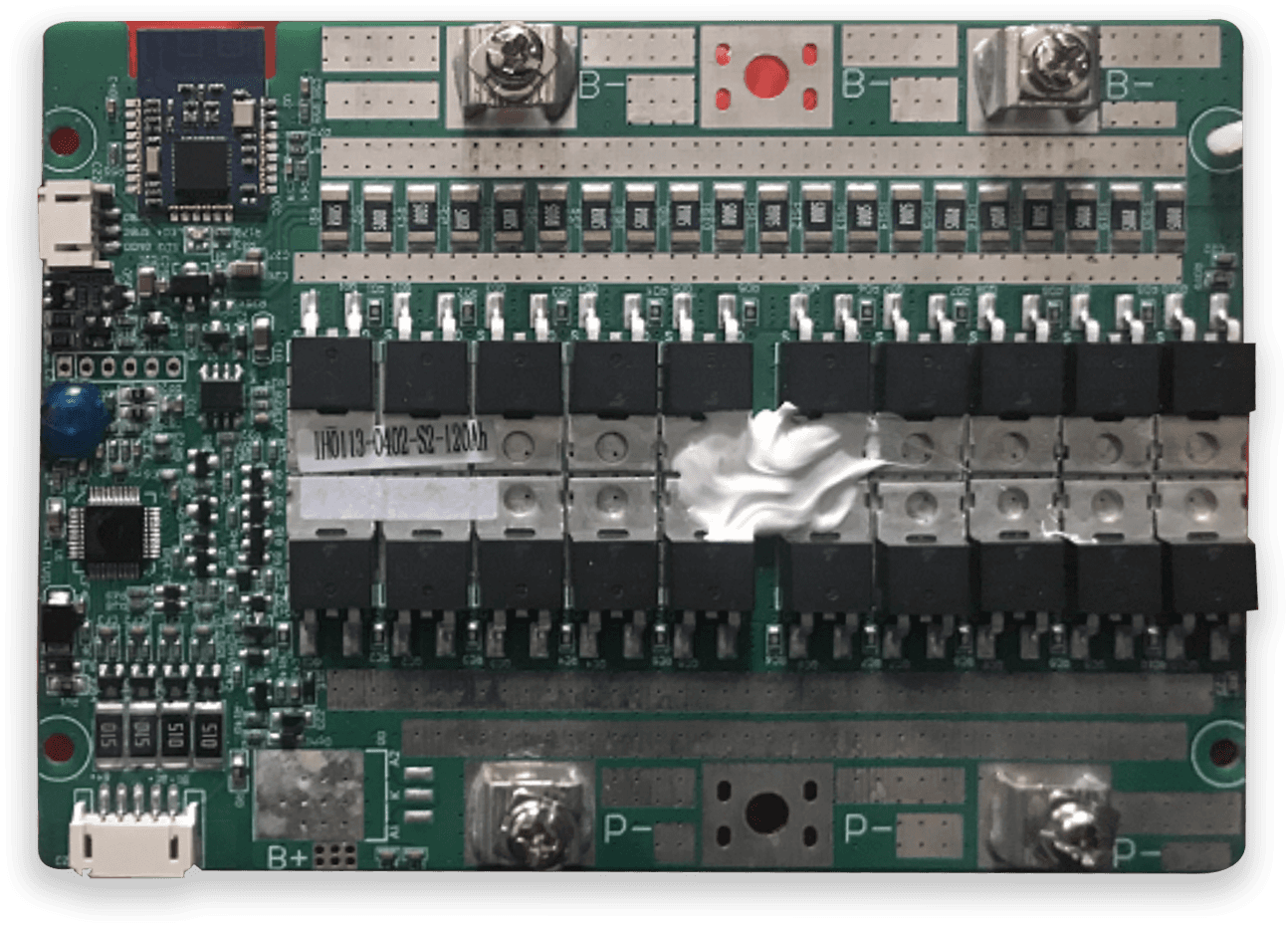

Every DCS LFP battery pack comes standard with detailed battery monitoring information via Bluetooth. (BLE 4.0 Technology)

The app can be downloaded to Android or iOS devices that are Bluetooth enabled.

Comprehensive battery monitoring information for DCS LFP batteries include

- SOC%. (State Of Charge)

- Battery pack voltage, Current & Power

- Time Remaining

- Individual Cell Voltage Status

- Battery Management MOSFET temperature

- Connectivity distance up to 10 metres.

Renaming Your Batteries Using The App

- Open the DCS LFP app and connect to the battery.

- Tap on the three horizontal lines on the top right hand corner of the screen.

- Input Password. 736263 > OK

- Name ………… > OK

- Refresh the battery list by tapping the circular arrow.

- Select custom and your battery will now appear in this section.

Modifications

Do not attempt to alter, modify or repair any part of the battery.

Any modifications to the battery will void your warranty.

Fully Discharged Battery

The BMS will emergency open the circuit of the battery terminals to protect the cells. Typically, you will see 3 - 4 volts across the battery terminals when using a multimeter. The BMS needs a 12V supply with at least 1A of current to release and wake up from a cell emergency protection state.

Most mains chargers with a lithium profile will do a slow recovery charge, as will most solar regulators. Some chargers on the market today that are advertised as ‘lithium’ compatible still don’t have the firmware to do a slow recovery charge to release BMSs. If you have a charger that will not wake up the BMS, the easiest way to wake it up is to connect an unregulated solar panel directly to the battery terminals; however, ensure all loads are disconnected before you do this. Having said that, every system should have a suitable low cut-off voltage to shutdown loads/accessories so that the batteries are not fully drained.

“Batteries cannot be left flat/empty; if the low voltage cutoff is triggered, the battery pack should be fully charged as soon as possible. If access to a suitable charger is not possible, disconnect all loads from the battery terminals. The warranty will be void if the battery pack has been left in a low voltage cutoff state for longer than 14 days.”

The most important thing is to isolate everything from the battery terminals, as cables/loads connected to the terminals cause more power drain as the FET gates have to remain closed to cull the accessory standby loads connected to the battery pack + offset BMS standby power consumption.

Incorrect State of Charge Due to a Synchronisation issue:

The state of charge is a calculated value by the BMS and will need to be reset (synchronised) every now and then.

The synchronisation process is automatic and is performed each time the battery is fully charged. The battery monitor (BMS) determines that the battery is fully charged when all 3 "charged" conditions have been met. The "charged" conditions for 12V batteries is:

Charged Voltage (> 14.0 Voltage)

Tail current (4% of battery capacity)

Charge detection time (1 minute)

Electrical Installations Standard ( AS/NZS 3001 . 2 : 2022 ) For Transportable Structures which includes Recreational Vehicles, Caravans etc.

Please note AS/NZS 3001 is made mandatory by electrical legislation in each state and territory.

The new standard includes requirements for “connectable electrical installation batteries” covering any battery that is installed with the primary purpose of supplying the living / accommodation features of a transportable structure, which includes recreational vehicles and caravans etc.

Below is a brief summary of some of the new requirements.

Lithium - Ion Batteries

- The location must be appropriate to ensure that the battery operates within the manufacturer’s defined operating temperatures and IP rating.

- Batteries must be located in a position that prevents any vented gases from entering a habitable area of the recreational vehicle. Any vented gases have to be vented externally from the vehicle. ventilation openings have a minimum vent area requirement, which is calculated based on the ratings of the battery. Any opening into the interior (habitable area) must be provided with an air seal.

- Any metallic service lines (eg. Gas, Diesel, Water etc.) located near the battery must be at least 300mm. clear of the battery terminals or must be shielded with dielectric material to prevent against short circuits.

- A battery must be secured to prevent movement. Restraints must prevent any movement under a pulling force of twice the battery weight.