Research and innovation in the battery world lead to a new generation battery version, improving backup battery banks’ stability. The earlier battery storage devices were bulky, inefficient and required continuous maintenance checks. The earliest battery bank used acid or distilled water-filled through its vents, and they need to be placed in a ventilated place to avoid any problem. The latest 75ah lithium battery by Deep Cycle Systems is all you need to power your electrical appliances, either connected with a grid or going off-grid.

Lithium-Ion Battery Technology

Lithium-Ion Battery Technology

The flooded-acid battery is still the most in service as it has been in service for over a century and a half. Since its invention in the early 1990s, the feature-rich lithium battery technology has captured a major market share due to its compatibility with a variety of applications. The modern features of a lithium-ion battery make it 5x efficient. It’s not a wonder that lithium batteries are part of almost every energy-hungry application with small to large power devices including, smartwatches, mobile phones, laptops, power tools, cameras, vehicles, military installations, medical equipment, aerospace, mobile food shops, media vans, campervans and solar systems.

Deep Cycle Battery

Lithium technology is reliable and offers deep-cycle lithium-ion battery units to either power individual electronic devices or power the entire home. As our name suggests, we are the best manufacturer of Deep Cycle Batteries built for heavy-duty performance 24/7. Our technology is robust enough to withstand the tough Australian weather conditions of the desert, so installing lithium batteries in any part of the country isn’t challenging. You can use a lithium battery as a starter battery due to its ability to provide high initial power and later use it as a regular deep cycle battery for power backup.

Maintenance-Free Battery

You need not worry about maintenance checkups, as our batteries are maintenance-free. Lithium batteries are free from adding up distilled water regularly to save battery cells from damage, like flooded acid batteries.

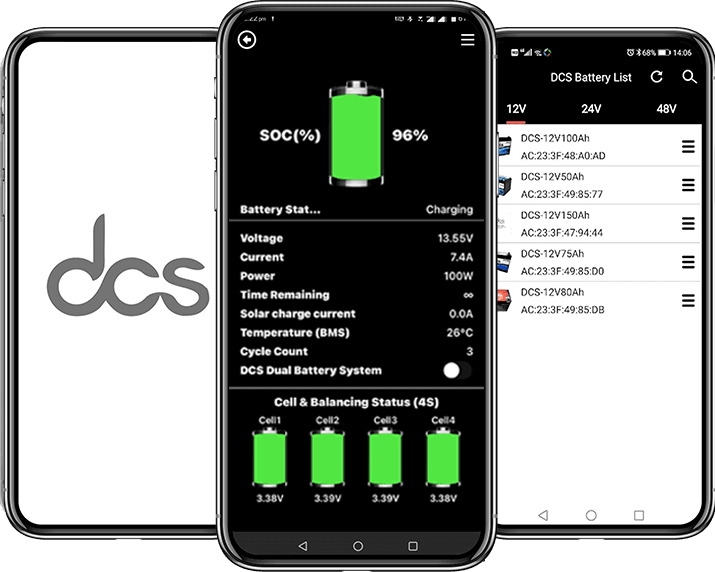

Virtual Control

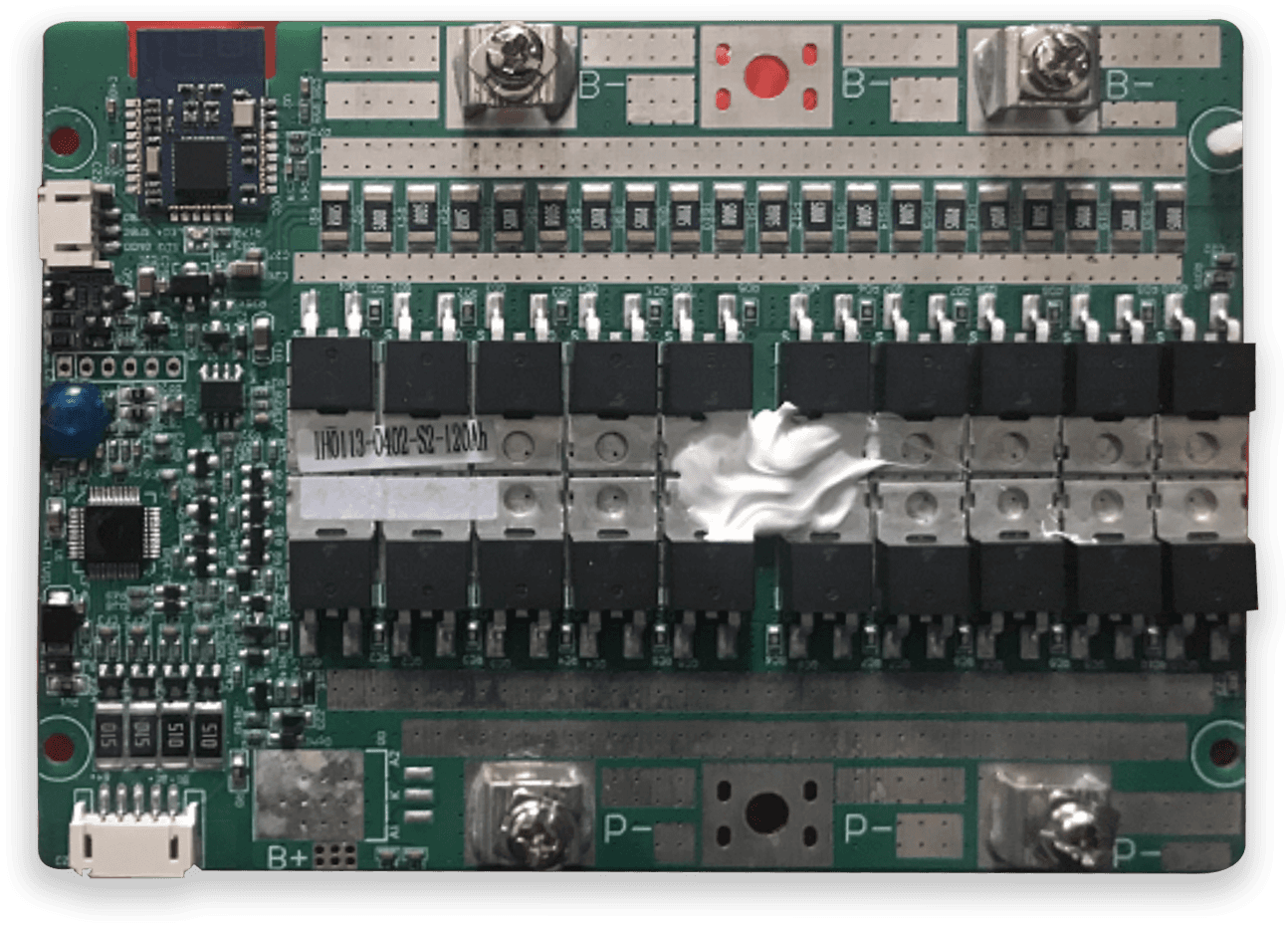

You are empowered to monitor and control various battery parameters using your mobile phone by connecting the power system via Bluetooth. Using a SmartSolar MPPT charge controller for your lithium battery, you have access to observe the battery performance, i.e. ampere-hours produced and consumed, can connect or disconnect loads and battery in certain conditions, i.e. under and overvoltage. The SmartSolar also provides safety to the battery in case of the high temperature of battery cells.

We are concerned about your safety; our battery production and other energy products have passed all the tough and challenging exams, certifications and benchmarks set by relevant safety departments. We use a three-stage charging method for our lithium batteries, including bulk charging, absorption, and float mode. Our MPPT charger ensures maximum power points tracking, resulting in a quick battery charge. MPPT is best for extracting every bit of available solar energy; it is the best and the only option for high efficiency even in the cloudy and winter season.

Battery Ampere Hours

Ampere hours are the capacity you want from your battery bank to power a certain amount of load. The ampere-hours of a battery depend on some circumstances, i.e. total load to power, backup time in hours and battery voltage. We can calculate the battery ampere-hours by multiplying the total load by hours and dividing it by battery voltage. For example, if you want to power devices of 225 watts for four hours with a 12v battery, you need a 75ah lithium battery to operate the devices smoothly.

Enjoy Thousands Of Life Cycles Of A 75ah Deep Cycle Battery

Enjoy Thousands Of Life Cycles Of A 75ah Deep Cycle Battery

The lead-acid batteries are recommended for a maximum of 50% discharge, which means that you can’t utilize the full potential of a lead-acid battery. A 75ah deep cycle battery will constantly provide you with more power without dropping voltage levels. That is the main reason for the quick success of such battery banks.

Batteries are crucial when using power, especially for portable devices, or when you want energy backup for your home or work site. The technological advancement in batteries allowed us to choose from a range of battery packs. A deep cycle battery has become the majority’s demand due to its unmatchable features compared with a traditional lead-acid battery. Deep cycle batteries are replacing outdated technology. We can find them in stock, where the need for small, medium and extensive power usages are required, i.e., mobile devices, laptops, power tools, vehicles, marine boats, aerospace, and military projects. The reason for the exponential popularity of deep cycle batteries is the ability to provide a deep discharge of up to 90%, which was impossible a couple of decades ago.

Deep Cycle Systems is a leader in the Australian energy market, serving families with affordable yet reliable and premium quality energy products to provide the best user experience. Our battery stockpile includes top-notch deep cycle battery collection meant for a longer life span that could be a decade. Our customers are happy that they got battery banks that can withstand harsh weather conditions, i.e., can operate in a temperate range between 5 to 60 degrees Celsius. These systems are maintenance-free to offer you a decade of service life.

Our deep cycle battery packs are lithium-based, known for their quality, deep discharge ability, quick charge time, and low self-discharge with under 3% of self-discharge during a month (depends on charge status).

What is a Charge Cycle?

What is a Charge Cycle?

A charge cycle refers to a procedure where a battery needs a charging aid and, after a full charge, discharges it to power certain AC loads. The charge cycle indicates the expected battery life. Typically, a deep cycle battery has thousands of charge cycles that make years of expected life in given circumstances. A deep discharge means using the battery’s full potential to utilize maximum output from it.

Voltage Level

A deep cycle battery is rated in two terms, i.e., ampere-hours and voltage level. A 75ah deep cycle battery tells the current supply to AC loads, while the voltage level describes the range of applications it can support. Typically, a 12v battery is used for most electrical appliances at home or in commercial use. 24v and 48v batteries are more common for motor vehicles, RVs, electric vehicles, and where more power is required for more significant projects.

75 Ah Lithium Battery for Engine Starting

At Deep Cycle Systems (DCS), we’ve engineered our 75 Ah Lithium Battery specifically for engine starting. We understand the importance of reliability when it comes to starting your engine, and our battery is designed to deliver consistent, high-quality performance. With our battery, you can trust that your engine will start swiftly and efficiently every time. We’ve built this battery to provide the high burst of energy needed for engine starting, ensuring that you have the power when you need it most.

Dependable Engine Start with Our Advanced Technology

Dependable Engine Start with Our Advanced Technology

Our 75 Ah Lithium Battery is more than just a battery; it’s a promise of reliability. When you choose DCS, you’re choosing a battery that’s designed with your needs in mind. Whether it’s for your car, boat, or any engine-starting application, our battery provides the assurance that your engine will start smoothly, even in demanding conditions.

12v 75ah Deep Cycle Battery – Ideal for Backup Energy Storage Requirements

Our 12v 75ah Deep Cycle Battery at Deep Cycle Systems is perfectly suited for your backup energy storage requirements. We understand that having a reliable power source is crucial for your peace of mind. That’s why we’ve developed a battery that not only meets but exceeds your expectations for backup energy. Our deep cycle battery offers long-lasting power, ensuring that you have the energy you need whenever you need it. It’s an ideal solution for home backup systems, emergency power, or any situation where reliable energy storage is essential.

Power Security in Your Hands

Power Security in Your Hands

With our 12v 75ah Deep Cycle Battery, you gain the power and security you deserve. We ensure that your energy needs are met with reliability and efficiency. You can rest easy knowing that our battery is safeguarding your power requirements and keeping your essential devices running smoothly during power outages or other emergencies.

12v 75ah Lithium Battery – Get 750 Lithium Cranking Amps for Engine Cranking

At Deep Cycle Systems, we’re proud to offer our 12v 75ah Lithium Battery, capable of delivering an impressive 750 lithium cranking amps for engine cranking. We know that starting your engine is about more than just turning a key; it’s about the confidence that your vehicle will respond when you need it to. That’s why our battery is designed to provide robust and reliable power for engine cranking. With our 12v 75ah Lithium Battery, you can expect a high-performance engine to start every time.

Unmatched Cranking Power When You Need It

Our commitment at DCS is to enhance your experience with unparalleled cranking power. The 750 lithium cranking amps in our 12v 75ah Lithium Battery ensure that you have the power you need for reliable engine starts. It’s our way of ensuring that you’re never left stranded, providing you with the power and reliability that you can count on.

75 Amp Lithium Battery – ABS Flame Retardant Plastic Make it Explosion Proof

75 Amp Lithium Battery – ABS Flame Retardant Plastic Make it Explosion Proof

At Deep Cycle Systems (DCS), we prioritize your safety, which is why our 75 Amp Lithium Battery is constructed with ABS flame retardant plastic, making it explosion proof. We understand that the safety of your equipment and environment is paramount. This design feature ensures that our battery not only meets but exceeds safety standards. When you choose our 75 Amp Lithium Battery, you’re investing in a product that offers peace of mind, assuring you that you’re using a battery that’s as safe as it is powerful.

Safe and Secure Energy Solution for You

With our explosion-proof design, you can confidently integrate our 75 Amp Lithium Battery into your systems, knowing that we’ve taken extra steps to ensure your safety. It’s our commitment to provide you with a secure and reliable energy solution so you can focus on your tasks without worrying about battery safety.

75ah Lifepo4 Battery – Operating Temperature Range is -30 to +110 degrees C

75ah Lifepo4 Battery – Operating Temperature Range is -30 to +110 degrees C

Our 75ah Lifepo4 Battery at Deep Cycle Systems features an impressive operating temperature range of -30 to +110 degrees Celsius. We understand that your energy needs can vary greatly depending on your environment. That’s why we’ve developed a battery capable of performing in extreme conditions. Whether you’re in a cold, frosty environment or dealing with scorching heat, our battery is designed to maintain its performance and reliability.

Reliable Performance in Any Environment

With this wide operating temperature range, our 75ah Lifepo4 Battery ensures that you have a reliable power source no matter where you are. You can trust our battery to deliver consistent performance, providing you with the power you need in any environmental condition.

DCS 75 Amp Hour Deep Cycle Battery with UN 38.3 Certifications

At Deep Cycle Systems, our 75 Amp Hour Deep Cycle Battery comes with UN 38.3 certifications, underscoring our commitment to quality and global standards. This certification is a testament to the safety and reliability of our battery, ensuring that it meets rigorous international transportation standards. When you choose our UN 38.3 certified battery, you’re choosing a product that meets high standards for transportation safety and quality.

Global Standard Assurance for Your Power Needs

Global Standard Assurance for Your Power Needs

Our UN 38.3 certification provides you with the assurance that our 75 Amp Hour Deep Cycle Battery is recognized globally for its safety and quality. You can be confident that you’re using a battery that is not only powerful and efficient but also meets stringent international safety standards. With DCS, you’re choosing a brand that stands for quality and reliability, ensuring that your power needs are always in good hands.

75 Amp Deep Cycle Battery with IEC 62133 & 62619, CE Certifications

At Deep Cycle Systems (DCS), our 75 Amp Deep Cycle Battery is not only efficient and reliable, but it also comes with IEC 62133 & 62619 and CE certifications. We understand the importance of adhering to international safety and quality standards. These certifications reflect our commitment to providing you with a product that meets stringent global requirements. Whether you’re using it for personal or professional purposes, our 75 Amp battery assures you of top-notch performance and adherence to safety norms.

Global Standards for Your Peace of Mind

With IEC 62133 & 62619 and CE certifications, you can be confident that our 75 Amp Deep Cycle Battery is a product you can trust. We ensure that our batteries meet the highest standards, giving you the peace of mind that comes from using a product that is recognized and respected worldwide for its quality and safety.

DCS Lithium Battery 75ah Comes with 4 Years Warranty

DCS Lithium Battery 75ah Comes with 4 Years Warranty

We at Deep Cycle Systems are proud to offer a 4-year warranty on our Lithium Battery 75ah. We stand behind the quality and durability of our products, and this warranty is our promise to you of our commitment to reliability and customer satisfaction. When you invest in our 75ah Lithium Battery, you’re not just getting a high-quality product; you’re also getting the assurance of our support for years to come.

Long-Term Assurance for Your Energy Needs

Our 4-year warranty on the 75ah Lithium Battery signifies our confidence in its longevity and performance. We want to ensure that you feel secure in your investment, knowing that we are here to support you with a reliable and enduring energy solution.

Lifepo4 Battery 12v 75ah – 3 Years Under Bonnet Warranty

Our Lifepo4 Battery 12v 75ah at Deep Cycle Systems comes with a special 3-year under-bonnet warranty. We recognize that batteries used in engine compartments face harsh conditions, and our warranty is designed to give you confidence in using our battery even in these demanding environments. This under-bonnet warranty is a testament to the robustness and resilience of our Lifepo4 Battery, ensuring it withstands the rigours of heat and vibration typically found in engine areas.

Specialized Warranty for Demanding Conditions

The 3-year under-bonnet warranty on our Lifepo4 Battery 12v 75ah is our assurance to you of its durability and suitability for challenging conditions. You can trust our battery to perform reliably under the bonnet, giving you the assurance of uninterrupted performance where and when you need it most.

12v 75ah Lithium Ion Battery – Virtual Control to Connect or Disconnect Loads and Battery in Certain Conditions

At Deep Cycle Systems (DCS), our 12v 75ah Lithium Ion Battery is designed with innovative virtual control capabilities. This allows you to connect or disconnect loads and the battery under specific conditions. We understand the importance of having control over your power usage, especially in varying conditions. Our battery’s virtual control feature gives you the flexibility to manage your power more efficiently and effectively. Whether it’s for energy conservation or operational safety, our battery provides you with the control you need.

Smart Power Management for Your Convenience

With our virtual control feature, you can effortlessly manage the power flow to your loads, ensuring optimal efficiency. This smart power management capability is particularly useful in applications where power requirements change frequently. With DCS, you’re getting more than just a battery; you’re getting a sophisticated energy solution that adapts to your needs.

Lifepo4 12v 75ah – Power a Load of 225 Watts to Get 4 Hours Backup Power

Our Lifepo4 12v 75ah battery at Deep Cycle Systems is perfectly suited for powering a load of 225 watts, providing you with 4 hours of backup power. We recognize the need for reliable backup power in various scenarios, from home energy systems to outdoor adventures. Our battery is designed to give you a dependable power source for extended periods. It’s ideal for situations where you need a consistent energy supply, ensuring that your devices and appliances keep running smoothly.

Reliable Backup Power When You Need It Most

With the ability to power a 225-watt load for 4 hours, our Lifepo4 12v 75ah battery offers you the backup power you need in critical situations. Whether you’re dealing with a power outage or need a portable power solution, our battery provides the assurance of continuous power, keeping your essential devices operational.

Deep Cycle Battery 12v 75ah – Get True Deep Discharge with DCS Lithium 75Ah Batteries

At Deep Cycle Systems, our Deep Cycle Battery 12v 75ah is engineered to provide true deep discharge capability. With our DCS Lithium 75Ah batteries, you get a product that can be discharged deeply without compromising its lifespan or performance. We understand the importance of having a deep cycle battery that delivers consistent power, even when drawn down extensively. Our batteries are designed to meet the demands of applications requiring deep discharging, ensuring that you have a reliable and enduring power source.

Maximized Energy Utilization for Your Needs

The true deep discharge capability of our Deep Cycle Battery 12v 75ah means you can fully utilize the battery’s capacity. This is essential for applications where every bit of energy counts. Our DCS Lithium 75Ah batteries ensure that you get the most out of your energy storage, providing you with a powerful and efficient energy solution.

12 Volt 75 Amp Deep Cycle Battery – Voltage Differences between Lithium and Lead-Acid Battery

12 Volt 75 Amp Deep Cycle Battery – Voltage Differences between Lithium and Lead-Acid Battery

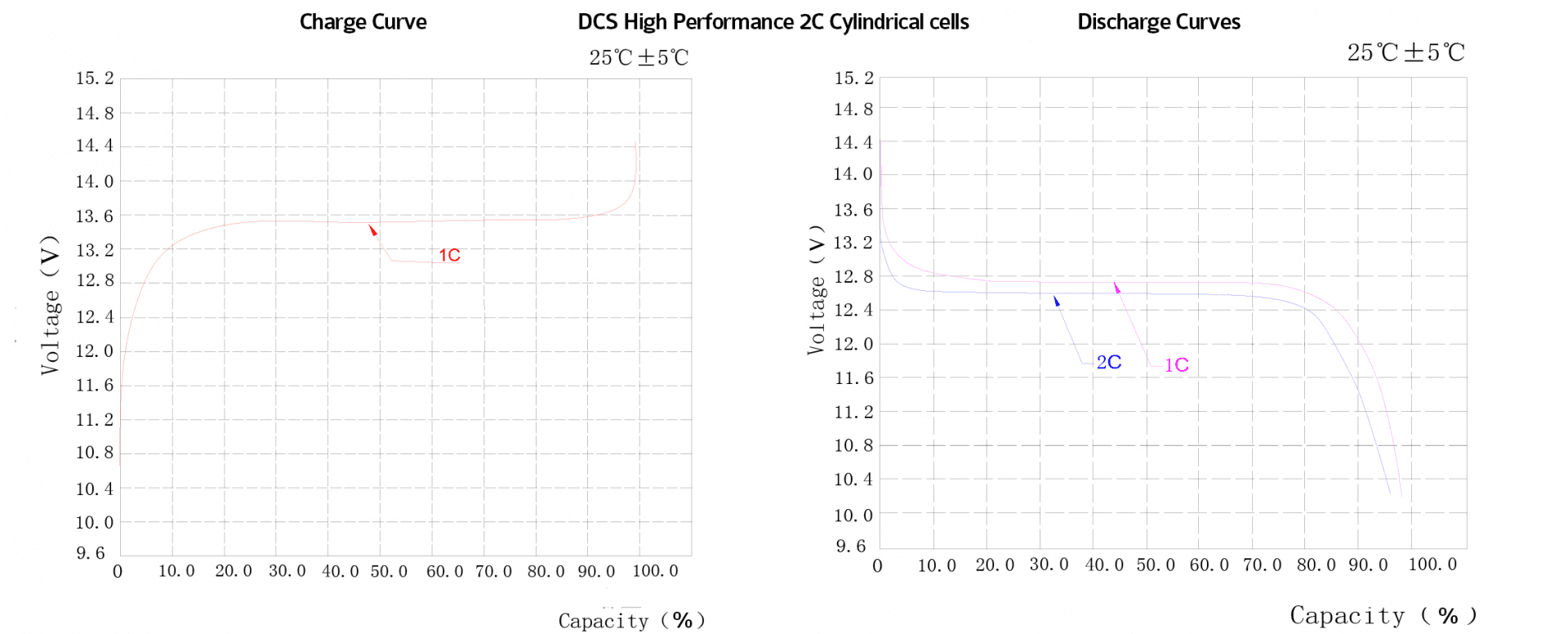

At Deep Cycle Systems (DCS), we understand the importance of knowing the differences in voltage characteristics between our 12 Volt 75 Amp Deep Cycle Lithium battery and traditional lead-acid batteries. Lithium batteries, including ours, typically offer a more stable voltage range throughout the discharge cycle compared to lead-acid. This means you can expect consistent power delivery without the significant voltage drop that often occurs in lead-acid batteries as they discharge. Our lithium battery maintains a higher voltage for a more extended period, ensuring that your devices and applications run effectively and efficiently.

Consistent Power Delivery for Your Devices

The stable voltage of our 12 Volt 75 Amp Deep Cycle Battery means that you get consistent power delivery, enhancing the performance of your devices. You won’t experience the usual power drop as the battery discharges, which is common with lead-acid batteries. This makes our lithium battery an ideal choice for applications that require a reliable and consistent power supply.

75 Amp Hour Lithium Ion Battery – IP54 for Ingress Protection

Our 75 Amp Hour Lithium Ion Battery at Deep Cycle Systems comes with an IP54 rating for ingress protection. This rating signifies that the battery is protected against dust ingress to a significant degree and splashing water from any direction. We’ve designed this battery to withstand challenging environmental conditions, ensuring that it remains safe and functional no matter where you use it. Whether it’s for outdoor, marine, or industrial applications, our battery is built to endure and perform.

Protected and Durable in Harsh Environments

The IP54 ingress protection of our 75 Amp Hour Lithium Ion Battery provides the assurance that it can withstand harsh environmental conditions. This durability is crucial for ensuring the longevity and reliability of your power source, giving you the confidence to use our battery in a variety of challenging settings.

75ah Deep Cycle Marine Battery – 2500 Lifecycles @100% DOD and More If Maintained Properly

At Deep Cycle Systems, our 75ah Deep Cycle Marine Battery is designed for longevity, offering up to 2500 lifecycles at 100% Depth of Discharge (DOD). This impressive lifecycle count is a testament to the quality and endurance of our battery. Moreover, with proper maintenance, the lifespan of the battery can be extended even further. We understand that in marine applications, reliability and durability are paramount. Our battery is built to provide consistent, long-lasting power, ensuring that you have the energy you need for your marine adventures or applications.

Extended Lifespan for Your Marine Adventures

With the potential for more than 2500 lifecycles at full discharge, our 75ah Deep Cycle Marine Battery is a reliable choice for prolonged use. Proper maintenance can further enhance its lifespan, ensuring that you have a dependable power source for your marine needs over the long term. Trust in our battery to power your marine journeys, knowing it’s built to last.

75ah Marine Battery – Store at 25 Degrees Celsius for Capacity Retention

Our 75ah Marine Battery at Deep Cycle Systems (DCS) is optimally designed for long-term capacity retention, especially when stored at 25 degrees Celsius. We understand that storage conditions can significantly impact a battery’s performance and lifespan. By storing our marine battery at this ideal temperature, you can ensure that it retains its capacity effectively and is ready to deliver optimal performance when you need it. This feature is particularly beneficial for seasonal marine users who may not use their battery continuously throughout the year.

Preserving Your Battery’s Health During Storage

Storing our 75ah Marine Battery at the recommended 25 degrees Celsius helps preserve its health and ensure its readiness for use. This storage guidance is part of our commitment to providing you with a reliable and durable power source, ensuring that your marine adventures are powered efficiently every time.

DCS Lithium Deep Cycle 75ah Battery is Capable to Provide 2C Discharge Rate to Get 150A

At Deep Cycle Systems, our Lithium Deep Cycle 75ah Battery stands out with its capability to provide a 2C discharge rate, delivering up to 150 amps. This high discharge rate capacity allows you to power high-demand applications efficiently, ensuring that your equipment receives the robust power supply it requires. Our battery’s ability to handle such high discharge rates makes it an ideal choice for applications that need a quick and powerful energy burst without compromising the battery’s longevity or performance.

High Power Output for Demanding Applications

The 2C discharge rate of our DCS Lithium Deep Cycle 75ah Battery translates to enhanced performance for demanding applications. Whether you’re using it for high-powered marine equipment, industrial tools, or any application requiring a significant power surge, our battery is engineered to meet those high demands reliably. This feature ensures that you get the power you need exactly when you need it, making our battery a versatile and powerful energy solution.

Contact Us

Deep Cycle Systems has been meeting the energy needs of Australian families for years. The trust of our customers is our pride; many of our new customers are referred by loyal clients. We are a team of experts in providing state-of-the-art energy solutions. Our products are manufactured to provide a longer life span without the need for regular maintenance visits that could dent your budget. Our products require initial installation usually, and you will enjoy the benefits for years. Give us a call at 1300 795 327 or write an email to us at info@deepcyclesystems.com.au.