Deep cycle batteries are applicable in usage for the following applications.

- Golf cart power for longer and efficient usage.

- Used in floor cleaning machines for constant power.

- Scissor lifts being operated by electricity in bigger malls and residential areas.

- Powering up forklifts.

- Provide power to recreational vehicles.

- Deep cycle batteries are used in trolling motors of the boat.

- Deep cycle batteries are used in navigational devices of small and larger boats.

- Deep cycle batteries provide clean and green renewable energy as compared to fossil fuel energy. Henceforth, it is good for the environment.

Deep cycle batteries are known to work great in multiple applications. However, some key factors make the deep cycle batteries far greater than the traditional lead-acid batteries.

Lithium Deep Cycle Battery For Extended Lifespan and Deep Discharge

The use of a power battery for storing electricity is significant as you can draw the current for connected loads when required without any disruption. The battery packs are helpful to phase out the scenario of power failure due to any reason. These batteries store electricity as direct current, and you need an inverter to convert the stored current into a compatible version, i.e., alternate current. There are many storage batteries in the market that have some unique features that make them stand alone from others. The lead-acid battery was the initial shape we got about 160 years ago; however, a lithium 50ah deep cycle battery is known as a heavy-duty battery pack to mitigate the issues of older versions.

Use of Power Battery

Battery packs increase efficiency in any case. The urban residents mostly use a power battery as a backup option in case of any likely power breakouts or grid failure. Typically they need a UPS or an inverter to manage the power management and conversation of DC to AC supply. The battery banks are also part of renewable energy sources, i.e., wind turbines and solar systems, to store extra produced energy for either peak hours or for non-solar production hours.

Types of Power Battery

Types of Power Battery

Power batteries are available in different modes with certain edges over others. Following are the main types of power batteries:

Lead-Acid Battery

Lead-Acid has the honour of the earliest storage battery serving for over a century and a half. It uses distilled acid water which is injected via its vents which becomes hectic for some people as if you didn’t fill it timely, it would become dead. The price of a flooded-acid battery is lower than others, which is a considerable advantage; however, it lacks the features of a dry battery. Typically, you would get at the most two-year life span from a lead-acid battery. A lead-acid battery has a fifty-percent discharge rating, which means you can draw only 50 ampere-hours from a 100 ampere-hour lead-acid battery. In short, you will get a half return on your investment.

Dry Cell Battery

Dry cell battery is the improved version of lead-acid battery, also known as gel battery. The dry cell deep cycle battery is suitable when you want a longer lifespan and a reliable power storage container.

Efficient working

We have already discussed earlier that deep cycle batteries are good for the constant provision of efficient power during usage. Deep cycle batteries are strong when put through the test, hence the reason these batteries are widely being adopted.

Easy to Maintain

A typical deep cycle battery needs nowhere near as much maintenance as a traditional lead-acid battery. Deep cycle batteries do not require active maintenance like a lead-acid battery. Henceforth they last for a longer amount of time.

Increased Durability

A 50ah lithium battery is much more stable in opposition to a normal car battery. Henceforth, it is much more durable as compared to other battery options, especially in the case of starter batteries. Deep Cycle batteries also have an increased ability to hold the charge and prevent discharge. Henceforth, they are more durable and reliable.

Why buy from Deep Cycle Systems?

Deep Cycle Systems is a prestigious energy solution provider. We have been in the business of providing our valuable customers with top-notch energy solutions products. Our ever-extending list of products includes inverters, solar systems, lithium batteries, solar batteries, solar panels, and deep cycle batteries. Deep Cycle Systems is committed to providing our valued customers with products at affordable prices. In addition, we offer expert installations to make our product buying and using experience seamless. Deep cycle systems believe in durable and reliable power solutions for our customers.

Lithium Ion 50 Amp Hour Deep Cycle Battery Can Be Discharged at 2C Rate

Lithium Ion 50 Amp Hour Deep Cycle Battery Can Be Discharged at 2C Rate

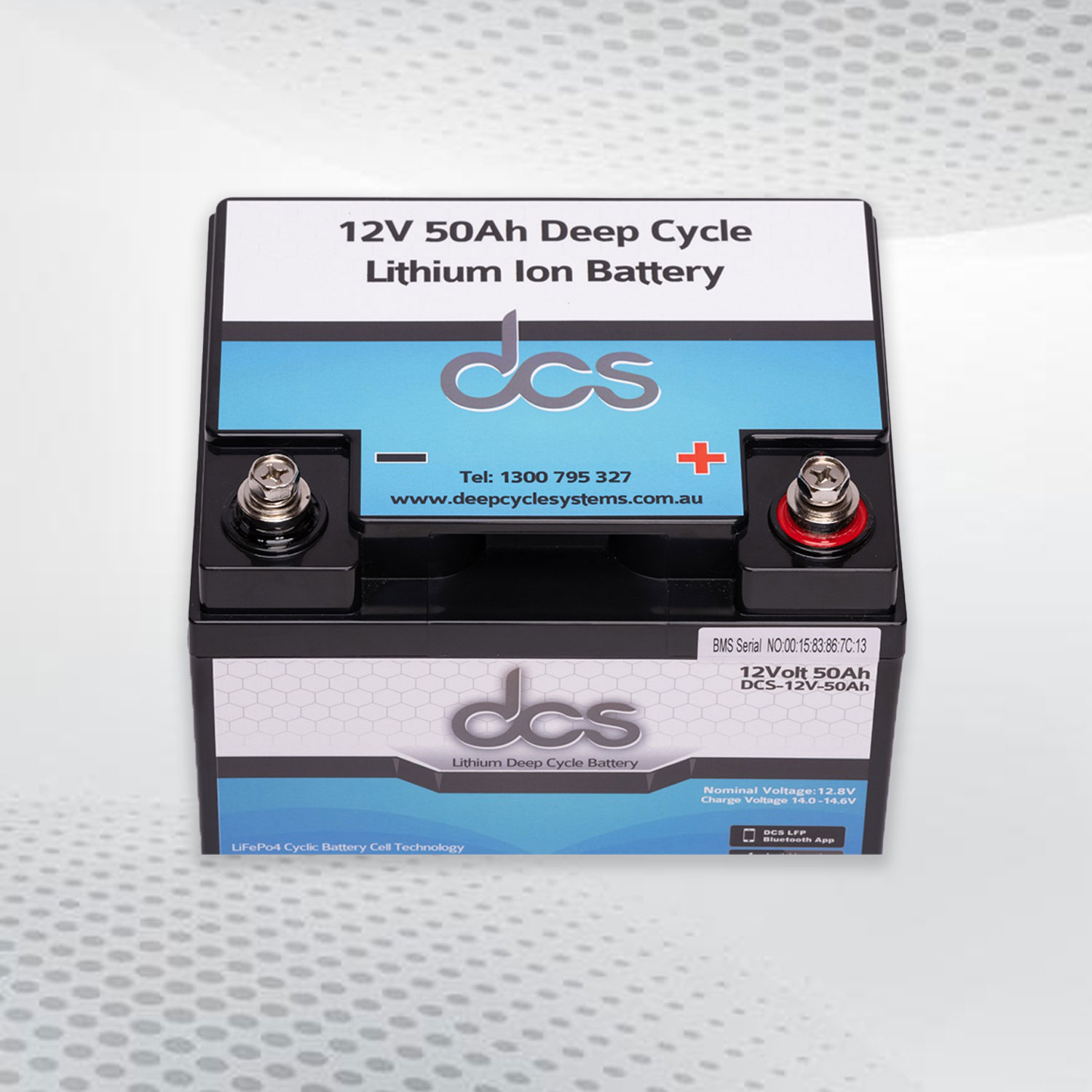

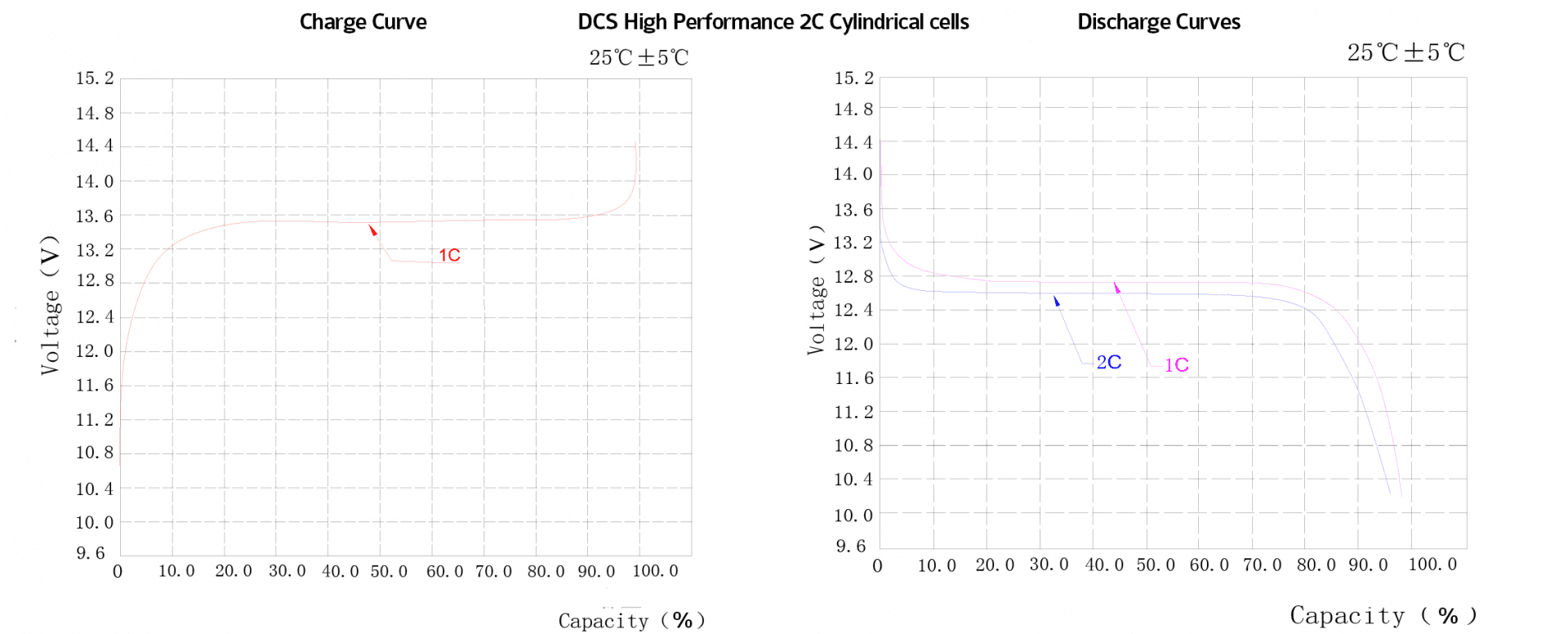

Deep Cycle Systems (DCS) introduces a high-performance Lithium Ion 50 Amp Hour Deep Cycle Battery, capable of being discharged at a 2C rate. This feature signifies the battery’s ability to be discharged at twice its capacity, meaning it can provide a 100 Amp output for a shorter duration. This high discharge rate is beneficial for applications that require a quick, powerful burst of energy. The 50 Amp hour battery from DCS is designed to meet the demands of high-drain devices and applications, offering robust power in a compact form.

50 Amp Hour Deep Cycle Battery – High Power Output for Demanding Applications

The 2C discharge rate capability of the DCS Lithium Ion 50 Amp Hour Deep Cycle Battery makes it exceptionally suitable for demanding applications that require a high power output in a short period. This feature provides users with the flexibility to power high-drain devices efficiently, ensuring reliable performance when it matters most.

12v 50ah Lithium Ion Battery – Get 2000 – 12000 Life Cycles

12v 50ah Lithium Ion Battery – Get 2000 – 12000 Life Cycles

DCS’s 12v 50ah Lithium Ion Battery stands out with its impressive lifespan, offering between 2000 and 12000 life cycles. This extensive range is indicative of the battery’s durability and the quality of its construction. The long life cycle ensures that the battery will provide a reliable power source over many years, making it a cost-effective investment in the long run. It’s an ideal choice for users looking for a dependable and long-lasting battery solution for their energy needs.

Long-Term Reliability and Cost-Effectiveness

The extensive life cycle range of the 12v 50ah Lithium Ion Battery from DCS translates to long-term reliability and reduced replacement costs. Users benefit from a sustainable power solution that maintains its efficiency over numerous charge and discharge cycles. This longevity is particularly advantageous for applications where frequent battery replacements are impractical or costly.

50 Amp Lithium Battery Design is Known for Its Super Low Internal Cell Resistance

50 Amp Lithium Battery Design is Known for Its Super Low Internal Cell Resistance

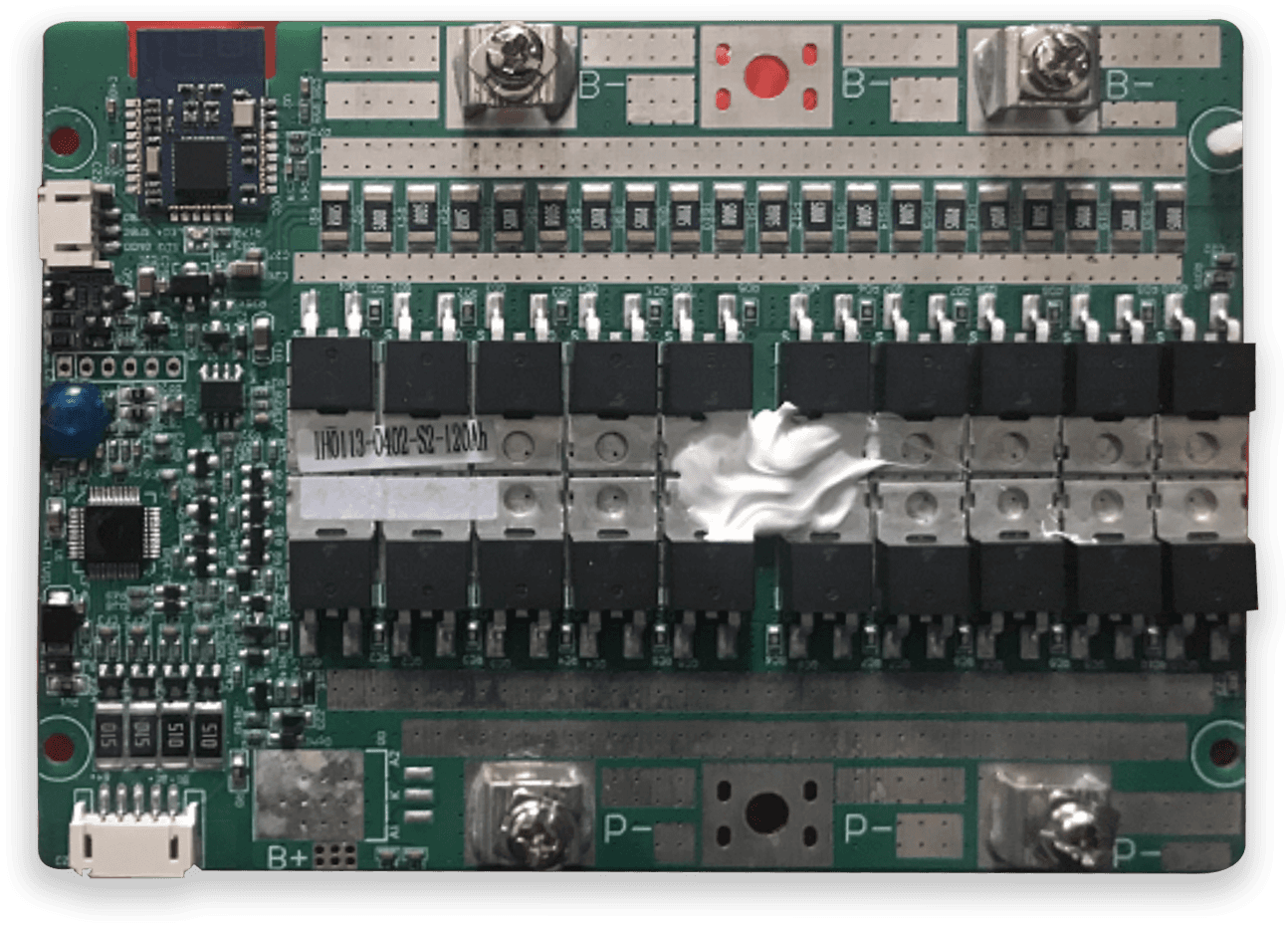

The design of the 50 Amp Lithium Battery from Deep Cycle Systems is renowned for its super low internal cell resistance. This low resistance is key to the battery’s high efficiency, as it minimizes energy loss during charging and discharging. The result is a more efficient transfer of energy, better performance, and reduced heat generation. This design feature makes the battery ideal for a wide range of applications, especially those requiring efficient and consistent power delivery.

Enhanced Efficiency and Performance

The super low internal cell resistance of DCS’s 50 Amp Lithium Battery enhances its overall performance and efficiency. This low resistance ensures that the battery can deliver its stored energy more effectively, providing a stable and reliable power source. It’s an essential attribute for users who require efficient energy management and consistent power delivery in their applications.

12 Volt 50ah Lithium Battery – Connect Up to 10 50Ah Batteries in Parallel Without Any External Communication System

Deep Cycle Systems (DCS) presents their versatile 12 Volt 50ah Lithium Battery, designed for seamless scalability. Users can connect up to 10 of these 50Ah batteries in parallel without the need for an external communication system. This feature offers significant flexibility in expanding power capacity, catering to larger energy requirements without complicated setups. The ability to parallel-connect these batteries effortlessly is a testament to DCS’s commitment to providing user-friendly, scalable power solutions. It’s ideal for applications ranging from home energy storage to commercial power systems, where scalable energy solutions are essential.

Effortless Expansion for Increased Power Needs

The capability to connect multiple 12 Volt 50ah Lithium Batteries in parallel from DCS allows users to scale up their power systems easily. This parallel connectivity feature is especially beneficial in scenarios where energy demands may increase over time. It provides a straightforward way to enhance power capacity, ensuring that the energy system can grow with the user’s needs.

50ah Lithium Ion Battery Has the Highest Charge Efficiency Rate of 98%

50ah Lithium Ion Battery Has the Highest Charge Efficiency Rate of 98%

DCS’s 50ah Lithium Ion Battery sets a high standard with its remarkable charge efficiency rate of 98%. This efficiency rate is among the highest in the industry, ensuring that almost all the energy used to charge the battery is effectively stored and available for use. Such a high charge efficiency minimizes energy loss, making the battery more economical and environmentally friendly. It’s an ideal choice for users seeking an efficient and sustainable power storage solution.

Maximizing Energy Utilization

The 98% charge efficiency rate of the 50ah Lithium Ion Battery from DCS signifies how effectively it utilizes energy. This high level of efficiency ensures that users get the most out of their energy input, making the battery highly suitable for applications where energy conservation and efficiency are priorities.

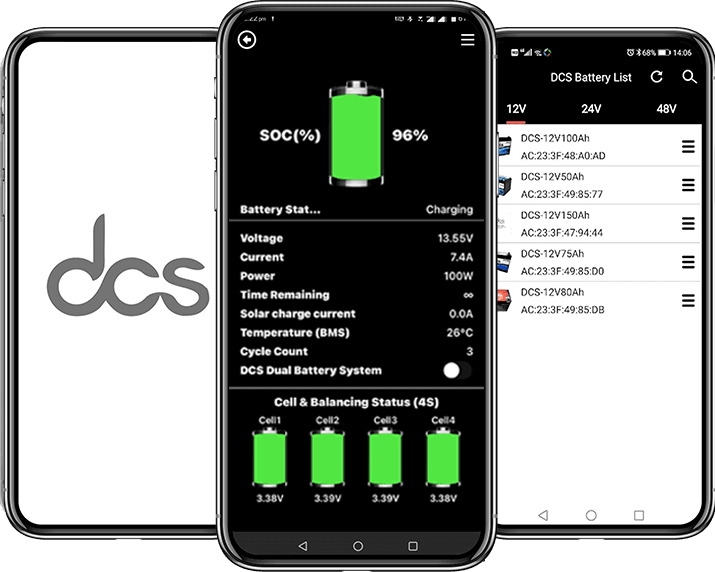

50ah Battery Lithium – Know About Battery State of Health with DCS LFP App

The 50ah Battery Lithium from Deep Cycle Systems comes with an added advantage – the ability to monitor the battery’s state of health through the DCS LFP App. This application allows users to keep track of various aspects of the battery’s performance and condition, such as charge levels, health status, and remaining lifespan. Having access to this information is crucial for maintaining the battery’s efficiency and prolonging its life. It offers users a comprehensive understanding of their battery’s status, facilitating informed maintenance and usage decisions.

Comprehensive Battery Monitoring at Your Fingertips

With the DCS LFP App, monitoring the state of health of the 50ah Battery Lithium becomes convenient and user-friendly. This digital tool enhances the user experience by providing vital information about the battery’s performance and health through a simple app interface. It empowers users to manage their batteries more effectively, ensuring optimal performance and longevity.

50 Ah Lithium Batteries – Monitor and Control Battery with DCS LFP App

50 Ah Lithium Batteries – Monitor and Control Battery with DCS LFP App

Deep Cycle Systems (DCS) enhances user experience with their 50 Ah Lithium Batteries, integrated with the innovative DCS LFP App for monitoring and control. This app allows users to seamlessly track and manage their battery’s performance directly from their smartphones. It provides real-time data on charge levels, usage patterns, and overall battery health, enabling efficient and informed battery management. This feature is particularly useful for users who need to keep a close eye on their power systems, ensuring their batteries are operating optimally at all times.

Enhanced User Interaction for Efficient Power Management

The integration of the DCS LFP App with the 50 Ah Lithium Batteries allows for enhanced user interaction, making power management more accessible and effective. Users can actively control and monitor their battery, adapting usage to maximize efficiency and lifespan. It represents a significant step forward in battery technology, combining high-performance power storage with smart, user-friendly features.

DCS Lithium 50Ah Battery Deep Cycle can be Stored @ 25 C without Losing its Capacity

DCS Lithium 50Ah Battery Deep Cycle can be Stored @ 25 C without Losing its Capacity

The DCS Lithium 50Ah Battery Deep Cycle is designed for exceptional stability and is able to be stored at 25 degrees Celsius without losing its capacity. This stability in storage conditions is a significant advantage for users who may not require constant use of the battery. It ensures that the battery maintains its charge over extended periods of inactivity, ready to deliver full power when needed. This feature makes the DCS 50Ah battery highly reliable and convenient for a variety of applications, including seasonal or backup power systems.

Reliable Performance Even in Prolonged Storage

DCS’s Lithium 50Ah Battery’s ability to retain its capacity at a stable storage temperature of 25 C ensures that it remains reliable over long storage periods. This reliability is crucial for users who need a battery that can be stored without frequent maintenance or worry about capacity degradation. It’s an ideal choice for systems where the battery may not be in regular use but needs to be ready to perform when required.

DCs 50Ah Deep Cycle – Operating Temperature Range is -25 to +80 degrees C

DCs 50Ah Deep Cycle – Operating Temperature Range is -25 to +80 degrees C

DCS’s 50Ah Deep Cycle battery boasts a wide operating temperature range, functioning efficiently between -25 to +80 degrees Celsius. This broad range of temperature tolerance is indicative of the battery’s robustness and adaptability to various environmental conditions. Whether used in colder climates or in hot, demanding environments, the DCS 50Ah battery ensures consistent performance and reliability. This adaptability makes it an excellent choice for a wide range of applications, including outdoor, marine, and industrial settings, where temperature fluctuations are common.

Adaptable Power Solution for Extreme Conditions

The wide operating temperature range of the DCS 50Ah Deep Cycle battery makes it a highly adaptable power solution for extreme conditions. It provides users with the assurance that their battery will function efficiently, regardless of the surrounding temperature. This versatility is a key aspect of DCS’s commitment to delivering high-quality, reliable power solutions that meet diverse user needs.

Li Ion 12v 50Ah – Fast and Efficient Charging than Other Battery Chemistries

Li Ion 12v 50Ah – Fast and Efficient Charging than Other Battery Chemistries

The Li Ion 12v 50Ah battery from Deep Cycle Systems (DCS) sets itself apart with its fast and efficient charging capabilities, surpassing other battery chemistries in performance. Lithium-ion technology enables quicker charge times compared to traditional lead-acid or AGM batteries, meaning less downtime and more usage. This efficiency is crucial for users who need a quick turnaround, such as in industrial, recreational, or emergency scenarios. DCS’s focus on rapid charging technology ensures that their batteries are not just powerful but also time-efficient, catering to the modern needs of energy storage.

Maximizing Time Efficiency with Advanced Charging

The advanced charging capabilities of the Li Ion 12v 50Ah battery make it a standout choice for applications requiring frequent or quick recharging. This feature enables users to get back to their tasks quicker, offering a practical solution in fast-paced environments. It’s an embodiment of DCS’s commitment to providing efficient and user-friendly power solutions.

DCS Li Ion 50Ah Batteries Have No Memory Effect like Lead-Acid or AGM Batteries

DCS’s Li Ion 50Ah batteries are engineered to eliminate the memory effect, a common issue with traditional lead-acid or AGM batteries. The memory effect refers to the reduction in battery capacity when repeatedly charged after being only partially discharged. The lithium-ion chemistry of DCS’s 50Ah batteries ensures they maintain their full capacity over time, regardless of their charge-discharge cycles. This feature is particularly beneficial for users who require consistent battery performance and longevity without the need for full discharge before recharging.

Consistent Performance Without Capacity Degradation

Consistent Performance Without Capacity Degradation

The absence of memory effect in DCS’s Li Ion 50Ah batteries means they deliver consistent performance without capacity degradation. Users can charge the batteries at their convenience without worrying about long-term capacity loss. This reliability is a significant advantage in maintaining efficient energy systems and underscores the superiority of lithium-ion technology in modern power storage solutions.

Li Ion Battery 50Ah – Get A Battery That Passed the MIL Vibration Testing Standards

The Li Ion Battery 50Ah from Deep Cycle Systems is not only efficient and reliable but also robust, having passed the rigorous MIL vibration testing standards. This certification indicates the battery’s resilience to physical stress, especially vibrations, making it suitable for use in demanding environments where durability is key. The MIL-standard vibration testing ensures that the battery can withstand the rigours of transport, industrial applications, and other challenging scenarios. DCS’s dedication to producing batteries that meet such high durability standards reflects their commitment to quality and reliability.

Durability in Demanding Environments

Passing the MIL vibration testing standards, the DCS Li Ion Battery 50Ah offers exceptional durability, capable of operating reliably in demanding environments. This resilience is particularly valuable for applications in mobile settings, outdoor use, or in conditions where mechanical stress is prevalent. Users can trust in the robustness of DCS’s batteries, ensuring uninterrupted power in even the toughest conditions.

Call Us

Deep Cycle Systems is an Australian-based energy solution provider. We have top-notch energy solutions, including solar panels, true sine wave inverters, heavy-duty battery banks, solar battery chargers, MPPT charge controllers, and solar accessories. Give us a call at 1300 597 327 to order our high-precision compact solar products for your home or work.