NORTH COAST OFFROAD CAMPER UP SPEC’ED WITH DCS

Feedback is an integral part of any businesses growth and development. Without it, a business has no sense of what is needed to keep its customers happy, and happy customers are a businesses best advertising. DCS welcomes feedback from all its customers. In this instance we are reviewing some positive feedback from a recent customer.

Terry from Brisbane purchased a new North Coast Campers – Caloundra Off road camper a few years ago and wanted to upgrade the electrical system from the standard lead acid setup to a larger Lithium based system, so he and his wife could spend longer periods off the grid and not have to look at or worry about the battery capacity and state of charge.

Below is the email that Terry sent through to DCS a few days after picking up his caravan after the upgrades.

“Positive and happy experience, with excellent results.

Paul from Deep Cycle Systems (DCS) recently upgraded the electrical system on my hybrid camper trailer. Before choosing Paul I had phoned other suppliers for quotes, and all they gave me was a price for lithium batteries, and nothing more.

However, when I spoke with Paul he clearly explained the different parts in a well designed electrical power system, and the long-term benefits of having such a system installed. This was the information I had been seeking.

I went up to Mount Tamborine and left with the camper with him for the install of lithium batteries, solar panels and the associated control hardware.

Wow, what a difference this has made! I now have 3 times the previous solar wattage, and 200 amp-hours 21stcentury lithium batteries, which are 42 kg lighter than the old lead acid batteries (technology from the previous century).

I am extremely pleased with how Paul designed, installed and tested this new system for me. Everything is very neat, and works perfectly. I am now looking forward to a decade of trouble-free power, making the system cost effective as well.

Paul is competent, consultative and customer focussed. He kept me informed of progress through regular text messages and photos, which I very much appreciated. I highly recommend Paul’s services.

Terry Johnsen

Brisbane”

North Coast Campers – Caloundra Off road camper

The upgrades;

The first step as always before commencing any works was to check over the entire electrical system, test the existing chargers, batteries, solar regulators, and inspect all cables and lugs.

These are the existing 2 x Lion 12V 100Ah AGM batteries,. After having been on a recovery charger for 24 hours they voltage tested at 11.0V = time for recycling.

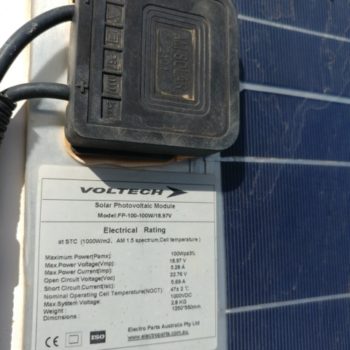

We inspected the panels and found that the junction boxes had been corroded internally and so the PV cell circuits were no longer providing correct connection integrity.

Existing Voltech 100W and 60W (total 160W) flat thin solar panels only produced a maximum of 1.5Amps at midday.

It took us over 2 hours just to remove these solar panels from Terry’s van, a careful operation to ensure no damage was caused to the roof.

We would like to warn customers to stay well clear of these flat thin designed solar panels such as these for a number of reasons;

- The junction boxes are completely exposed to the elements, so it’s only a matter of time before the weather penetrates inside and starts to corrode the connections.

- There is no ventilation provided to the underside of the individual cells and so the conversion efficiency in full sunlight is terrible due to the cells overheating.

- Many have poor warranties. The standard on such solar panels is usually only 2 years.

- Overpriced.

Due to the highly competitive solar industry in Australia and the reduction of government solar panel subsidies, solar panels have come down significantly in price in the last 2 years.

Quality commercial solar panels with a 10 year warranty are now one of the cheapest components in a well designed caravan system.

We upgraded Terry’s van to 2 x 270W CSun Mono solar panels (540W) and in conjunction with the correct mounting brackets, provides sufficient air ventilation for superior performance and longevity. Commercial panels are backed by a 10 year warranty.

What a difference some quality solar panels make. The current jumped from 1.5A to 15.2A. The existing Voltech MPPT solar regulator is rated to 30A, and so it now has a chance in providing up to 30A in perfect conditions.

Next, 2 x DCS 12V 100Ah batteries were paralleled to provide a total of 12V 200Ah of usable storage and positioned and secured into place with some additional timber bracing to ensure they cannot move around, especially on corrugated roads. DCS lithium batteries are built with a completely rigid internal chassis so the cells and BMS board cannot move and this design ensures that exposure to long term corrugated road conditions won’t effect their performance.

2 x DCS 12V 100Ah batteries paralleled to provide 12V 200Ah capacity, with 96% usable storage.

An Enerdrive DC2DC 30Amp charger was installed to enable correct charging from the vehicle.

The DC2DC charger features an integrated MPPT regulator and will happily take some extra portable solar panels if ever the need arises.

60A VSR (voltage sensing relay) protector installed to main load circuit. The ideal setup is to have all chargers wired directly to the DCS batteries and all load circuits protected via a VSR or otherwise known as a smart battery protector.

60A VSR (voltage sensing relay) protector installed to main load circuit. Cut off at 11.5V.

The DCS 12V lithium batteries can be cycled to their full 100% capacity, however it’s difficult to catch them during the last 5% SOC due to the nature of lithium cells having a very flat charge and discharge curve. If you’ve ever used lithium power tools you’ll know exactly what we mean, they will deliver a nice consistent linear power delivery and then very quickly drop off and shutdown.

This is a typical characteristic of lithium ion cell technology. So ideally you want to cycle and use about 95% DOD (5% SOC remaining). We recommend the installation of a VSR (voltage sensing relay) which should be set to cut off loads at 11.5V. That way if your loads ever empty the batteries out the VSR will cut your loads at 11.5V. That will allow the batteries to standby for several days until they can be recharged again. If the batteries are installed in a system without a VSR set to 11.5V the internal BMS will open circuit the terminals between 10.0 – 11.0V and shut the batteries down, we refer to this as sleep/protection mode. As the terminals don’t provide any resistance or voltage, most chargers won’t recognise that the batteries are still connected to them and so won’t automatically resume charging.

The only way to wake the batteries up from this mode is to apply another 12V power source to the terminals such as a vehicle alternator or another 12V battery as soon as a little charging current has flowed into the DCS batteries after a few seconds the BMS will wakeup and resume service. It’s also important to note that should you ever empty the DCS batteries it’s important that the batteries return to a minimum 50% SOC as soon as possible so that no permanent capacity loss occurs.

The existing voltage meter is an adequate reference of the batteries SOC. You don’t need complex battery monitors. We recommend a good quality voltage meter that can display 2 decimal places. After living with lithium ion batteries after a few days/weeks you will learn and memorise how the voltages correspond to the SOC. As a rule of thumb under a charging state, anything above 14.0V is fully charged 100% SOC.

Under a discharging state,

- Voltages around 13.6V you are around 90% SOC.

- Voltages around 13.0V you are around 50% SOC.

- Voltages around 12.0V means you only have around 10% SOC.

If the DCS batteries are regularly getting sufficient charging currents the batteries should cycle between 12.8V ~ 13.6V most of the time.

The above upgrades are standard inclusions for DCS customers upgrading to the superior performance and weight savings associated with DCS 12V batteries. When failure ins’t an option use only DCS 12V lithium ion batteries.