The ARENA-funded Battery Test Centre in Canberra was a groundbreaking initiative designed to rigorously assess the performance and durability of various 48V lithium battery packs available for supply between 2017 and 2019. This ambitious program provided invaluable insights into battery longevity, efficiency, and resilience under extreme conditions.

In 2019, DCS was invited to participate in the third and final phase of testing by submitting one of its PV series battery packs. However, due to existing commitments for our latest GEN2 PV series 13.5kWh stock—allocated to projects spanning 2019/2020—we were unable to supply a new unit for testing. Instead, we contributed a well-used GEN1 PV 10kWh battery pack from our workshop, which had already been in operation for approximately four years. This allowed us to remain part of the program while putting an aged battery to the test under rigorous conditions.

Key Findings from Public Report 12

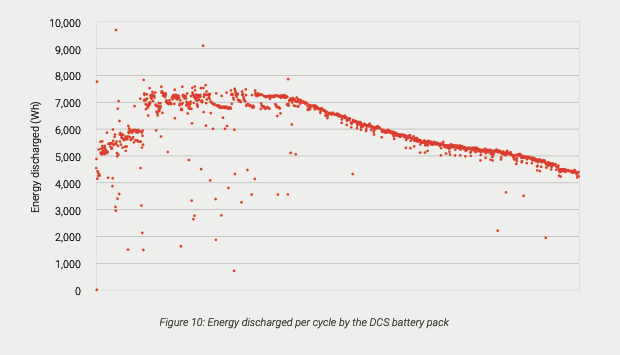

Upon commencement, our battery began cycling at a robust 7kWh, as evident in the first ~300 cycles in the below graph while the test centre optimised its integration with SMA inverters. By the conclusion of Phase 3, the battery had successfully completed approximately 1,100 cycles, displaying a steady capacity fade due to natural aging and cell degradation. Despite this, the unit remained fully operational, maintaining a reliable 4.5kWh capacity without any reported faults.

The testing program included:

Phase 1: 8 battery brands

Phase 2: 10 battery brands

Phase 3: 8 battery brands

Out of the 26 battery brands assessed, only 9 successfully completed their testing phase without failure—a testament to their engineering and reliability. We were proud to see that our GEN1 DCS battery was among the select few to withstand the gruelling test conditions. This achievement was particularly notable considering that our GEN1 batteries were originally designed in the early 2010s.

Understanding the High Failure Rate: Why Did 65% of Batteries Fail?

- Extreme Stress Testing

The testing environment was particularly harsh, pushing batteries far beyond typical real-world usage. Each unit underwent three full charge-discharge cycles daily and was exposed to ambient temperature fluctuations ranging from 10°C to 37°C.

For perspective, a well-designed off-grid system typically utilises around 30% of its battery capacity per night, translating to a single cycle every three days—or approximately 120 cycles annually. Even in extreme cases, where system capacity is undersized, annual cycle counts rarely exceed 200 cycles. By contrast, the test conditions imposed an 800% increase in duty cycling, which accelerated wear and exposed design weaknesses.

Unsurprisingly, many batteries on the market at the time were not engineered to withstand such relentless punishment. However, those that successfully completed the test demonstrated superior mechanical design and battery management system (BMS) capabilities, affirming their resilience and quality.

- Electrochemical Composition

The stress testing underscored the limitations of Nickel Manganese Cobalt (NMC) cell chemistry, which exhibited poor cycle life and proved unsuitable for Energy Storage Systems (ESS). While NMC technology offers high energy density—making it the preferred choice for Electric Vehicles (EVs)—its durability in stationary applications is significantly lower.

This insight raises concerns about Vehicle-to-Grid (V2G) integration, where bidirectional charging could further degrade NMC-based EV battery packs, potentially voiding warranties and accelerating battery replacement cycles.

Conversely, batteries utilising Lithium Iron Phosphate (LFP) cell chemistry demonstrated exceptional reliability. Given that LFP technology offers at least double the cycle life of NMC at the time, its superior performance in stationary storage applications was both expected and validated through the test results.

- The Evolution of Battery Storage Technology

The late 2010s marked the dawn of a new era in battery storage technology. For decades, lead-acid batteries had dominated the landscape, but advancements in lithium-ion chemistry began reshaping the industry.

A pivotal breakthrough came in the late 1990s, when John Goodenough, a professor at The University of Texas in Austin, pioneered the development of LFP cathode material. His research laid the foundation for modern lithium-ion batteries, enabling the widespread adoption of rechargeable battery systems across industries—from consumer electronics to EVs and residential energy storage. In 2019, Goodenough was awarded the Nobel Prize in Chemistry, alongside Whittingham and Yoshino, for their collective contributions to lithium-ion battery innovation.

Fast forward to 2025, and the landscape has evolved dramatically. The latest generation of 48V battery systems has benefitted from rapid advancements in LFP technology, significantly improving energy density, cycle life, and reliability. If the same stress test were conducted today, we would undoubtedly see a stark contrast in performance, highlighting the progress made over the past few years.

Conclusion: The Fast-Paced Evolution of Battery Storage

The battery storage industry is a rapidly evolving and highly competitive market, where technological innovation determines longevity. Over the years, numerous startups have emerged and faded, and companies have filed for bankruptcy in their pursuit of viable energy storage solutions.

At DCS, we remain at the forefront of this dynamic industry. As a small Australian company, we have invested over $10 million of our own capital into developing a next-generation Battery Management System (BMS) and our high-performance 48V 15kWh batteries. These cutting-edge energy storage solutions leverage the latest ultra long-life LFP cell chemistry, managed by an advanced BMS that maximises efficiency and longevity.

As the energy sector continues to evolve, DCS remains committed to innovation, reliability, and performance – ensuring that our batteries set the benchmark for excellence in energy storage solutions.

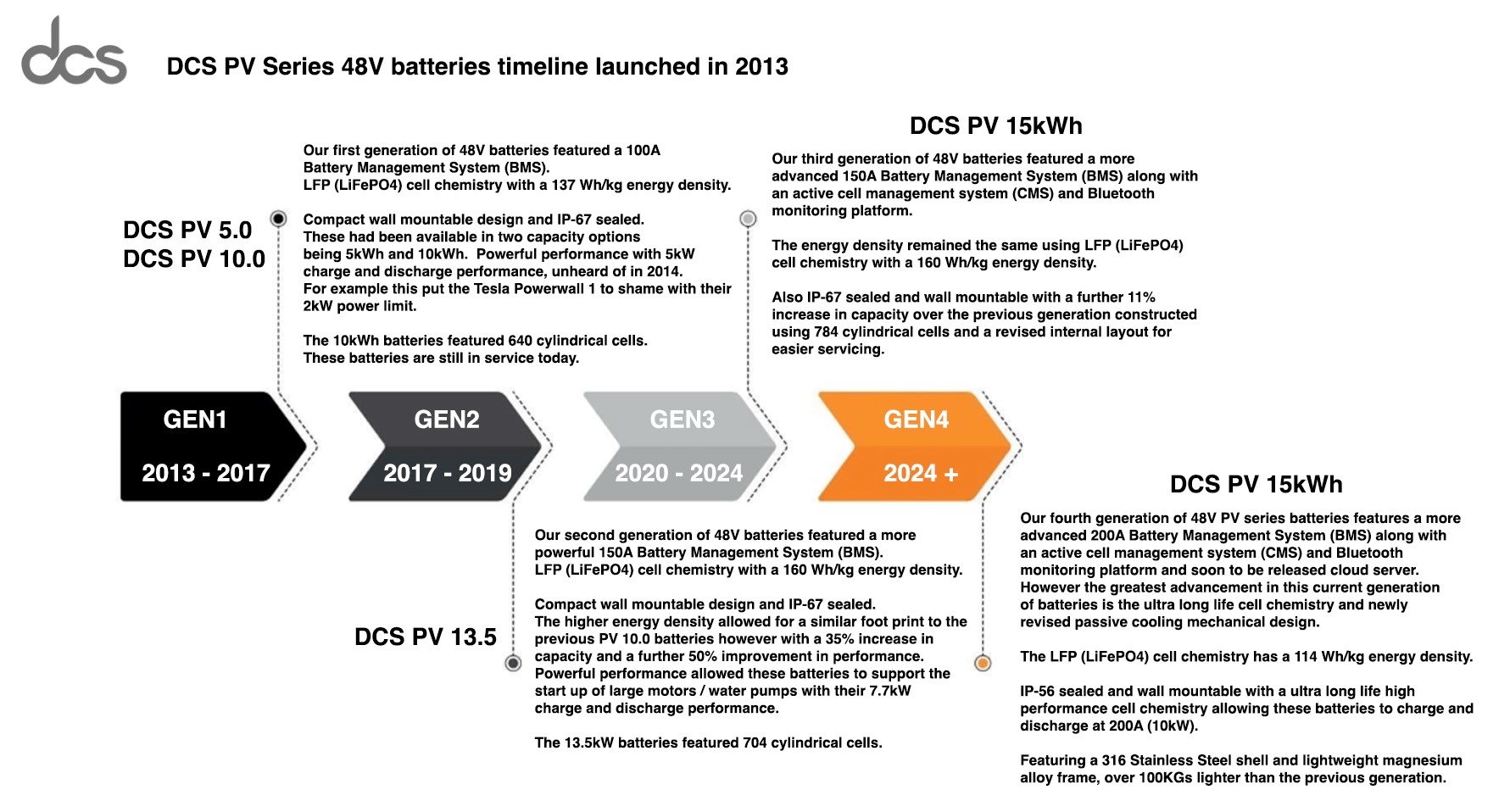

The timeline below outlines the evolution of the DCS PV Series batteries since 2013, highlighting key advancements and innovations introduced with each generation. For more information you can visit the product page here: https://www.deepcyclesystems.com.au/product/pv-series-hybrid-off-grid/